Tempered glass panels are everywhere — in shower doors, vehicle windows, entry doors, shelves, and countless home and commercial applications.

Yet, many people don’t know what makes it unique until it breaks. Unlike standard glass, which fractures into sharp, dangerous shards, tempered glass shatters into small, pebble-like cubes. This distinct break pattern is one of the biggest reasons builders and manufacturers widely use it as a safety material.

But why does tempered glass shatter differently, and what does that reveal about tempered glass strength? Understanding the science behind its design helps you choose the safest materials for your home and gives insight into how tempered glass breaks when it fails.

This guide explains how manufacturers create tempered glass, what makes it stronger than standard glass, and why its signature shatter pattern occurs. You’ll also find answers to some of the most common questions people ask about tempered glass performance, breakage, and safety.

What tempered glass is and why it’s different

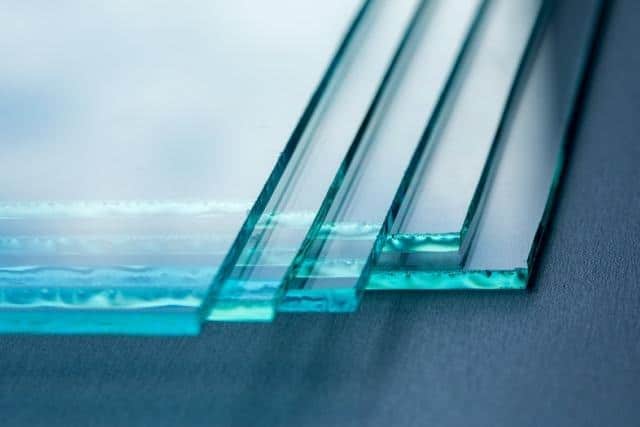

Tempered glass is a type of safety glass engineered through a specialized heat-treating process. While regular annealed glass is cooled slowly after production, tempered glass panels are reheated to extremely high temperatures and then rapidly cooled, creating surface compression and interior tension.

These opposing forces dramatically increase tempered glass strength, making it four to five times stronger than standard glass.

This manufacturing method is the reason tempered glass breaks differently from regular glass. When tempered glass fails, the internal tension forces it to break into small, dull fragments instead of long, sharp shards. This reduces the risk of severe cuts or injuries, making it ideal for high-impact or high-traffic areas.

How manufacturers create tempered glass

The tempering process begins with cutting and shaping the glass to its final dimensions. Once manufacturers temper the glass, any attempt to cut it will cause it to shatter immediately. After shaping, the glass is heated to approximately 1,100°F and then rapidly cooled with high-pressure air. This creates two layers: an outer layer in compression and an inner layer in tension.

These forces determine how tempered glass panels break. The compressed outer surface resists force and impact far better than standard glass. However, if damage penetrates the compression layer — especially near the edges — the tension inside the glass releases instantly, causing the entire surface to shatter into controlled, cube-like pieces.

This engineered break pattern is the foundation of tempered glass strength and safety.

Why tempered glass shatters differently

The unique shatter pattern is the result of internal pressure locked inside the glass. When the compression layer is compromised, the tension inside forces the glass to break all at once. Instead of forming dangerous shards, tempered glass crumbles into thousands of small, blunt pieces.

Understanding how tempered glass panels break shows why people trust it for safety applications — its break pattern helps protect people from serious injuries.

Is tempered glass unbreakable?

No, tempered glass is not unbreakable, despite its reputation for durability. Due to its strength, many assume it withstands anything. However, even with enhanced tempered glass strength, it still has break points.

Tempered glass may break when exposed to:

- Sudden impact from a pointed object

- Damage to edges or corners

- Repeated stress in a localized area

- Manufacturing imperfections

- Extreme temperature changes

It resists blunt force well, but its edges remain its most vulnerable point.

How much force does it take to break tempered glass?

There is no single exact measurement because force varies by thickness, size, installation, and temperature. However, tempered glass panels generally require four to five times more force to break than annealed glass of the same thickness.

Blunt force often bounces off, but a sharp object with a small point of impact may compromise the compression layer, triggering immediate failure. That is why car safety tools use small metal points — to intentionally trigger how tempered glass breaks during a rescue.

What damages tempered glass?

Because of its unique structure, several factors undermine tempered glass strength:

Edge chips or cracks:

Edges experience the highest internal tension. Any damage here weakens the entire panel.

Thermal stress:

Localized heat (like from appliances or sunlight, magnified by reflective surfaces) causes uneven expansion.

Improper installation:

Uneven pressure, incorrect hardware, or overly tight framing create stress points.

Manufacturing imperfections:

Nickel sulfide inclusions, though rare, expand and trigger spontaneous breakage.

When these vulnerabilities appear, they determine how tempered glass breaks and why the entire sheet shatters instantly, rather than breaking gradually.

How does tempered glass look when it breaks?

Tempered glass panels break into small, uniform cube-like pieces often referred to as “dice.” This predictable break pattern helps prevent severe cuts, limits the formation of large, dangerous fragments, and signals that the glass was fully tempered.

The appearance is vastly different from that of annealed glass, which fractures into sharp, jagged shards that can cause significant injury. These dice-like fragments remain one of the clearest visual indicators of how tempered glass breaks compared to standard glass.

Can tempered glass break easily?

In everyday use, tempered glass is less likely to break easily. Its enhanced strength is one of its defining features, allowing it to withstand heavy loads, blunt impacts, and pressure spread across large areas.

However, it will still break suddenly and dramatically under the right conditions. When excessive force is concentrated at a single point, when something strikes its edge, or when extreme temperature variations occur, these stresses compromise the glass’s stability and cause it to fail.

This balance — highly durable during normal use yet vulnerable under specific types of stress — is central to understanding tempered glass strength.

Is tempered glass expensive?

Tempered glass does cost more than standard annealed glass, but the added safety, durability, and performance justify the investment. Prices vary based on thickness, size, and custom cutting. Compared to laminated or specialty safety glass, tempered glass is still one of the most affordable options.

Because it lasts longer and offers enhanced safety, many homeowners consider it a cost-effective upgrade, especially during remodels that require durable, code-compliant glass.

Can tempered glass be cut easily?

No — once manufacturers temper the glass, you cannot cut, drill, or reshape it. Attempting to do so will immediately compromise the compression layer and cause the entire panel to shatter.

Manufacturers cut the glass to the correct size or shape before tempering it. This is why professionals handling glass always emphasize the importance of precise measurements and careful planning.

How to spot tempered glass

You can identify tempered glass in several ways:

- A small etched safety stamp in a corner

- Viewing stress patterns using polarized lenses

- The break pattern, if it shatters

- Professional testing or verification

Because building codes often require tempered glass in certain locations, such as bathrooms, entry doors, and near floors, it’s essential to know whether a pane meets safety standards.

Applications where tempered glass strength matters

Builders and manufacturers use tempered glass in areas where safety, durability, and predictable breakage are essential. This includes:

- Shower doors

- Doors with sidelites

- Balcony railings

- Gym and studio mirrors

- Tabletops and shelves

- Entry doors and commercial storefronts

Its combination of resilience and safe breakage makes it ideal for environments where both performance and safety are priorities.

Understanding how tempered glass breaks helps you choose safer materials — and Murray Glass can help.

Tempered glass remains one of the most reliable and widely used safety materials in residential and commercial design. By understanding tempered glass strength, the science behind its manufacturing, and how tempered glass breaks, you can make informed decisions about where and when to use it in your home.

If you need tempered glass installation or replacement, Murray Glass helps you select and install the right safety glass for your space. Contact Murray Glass today to get expert guidance and schedule your tempered glass service.